meta data for this page

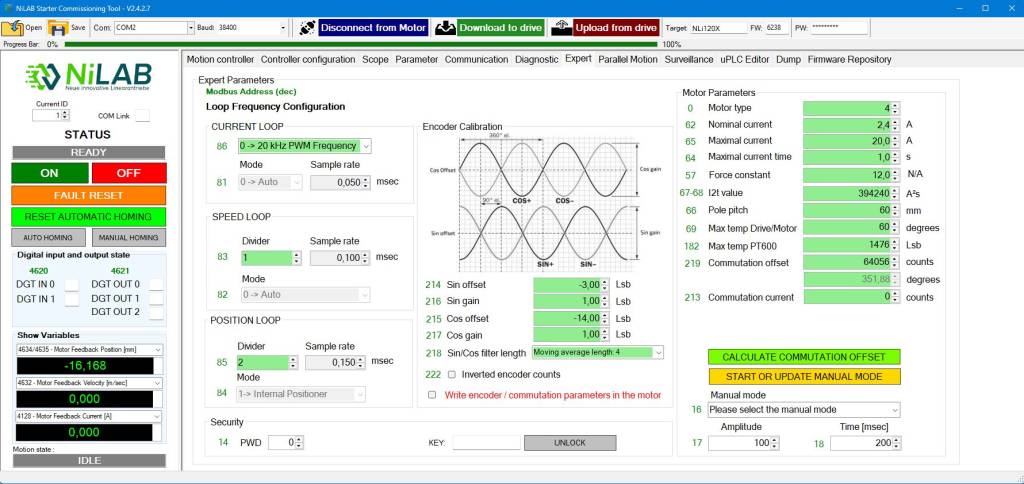

Expert Mode

Expert mode is intended for expert user only.

This window provides access for changing the motor parameters and due to the risk to damage the motor is protected by a specific password.

Please contact NiLAB technical support to receive the password to unlock this functionality.

- increase the peak current ⇒ Parameter 65

- change the max admissibile temperature of the motor and the coil ⇒ Parameters 69 and Parameter 182

- change the control loop frequencies ⇒ Parameters 83 and 85

- change the encoder calibration and filtering ⇒ Parameters 214,215,216,217, 218

- setting the offset of the homing ⇒ Parameter 48 and 49.

- change the pole pitch use for determining the right mechanical position ⇒ Parameter 66

- change the PWM frequency ⇒ Parameter 86

Electrical angle to Mechanical angle using pole pitch value

Please consider that the Parameter 66 is used to convert the electrical angle to the mechanical angle ⇒ mechanical positions.

The right number in respect to the motor size are:

| Motor size | Pole pitch | Unit |

| NLi080Q | 30 | mm |

| NLi080X | 30 | mm |

| NLi120Q | 60 | mm |

| NLi120X | 60 | mm |

Note that if this value is not the same as in the table above, the motor works but the mechanical space do not correspond to the real mechanical movements.

Max temp PT600 LSB value calculation

The parameter 182 is used to compare the value of the analog input where a PTC600 thermal sensor is internally connected.

The PTC600 is available on for NLi120Q and NLi120X motor sizes.

| Coil temp | PTC600 Resistance | Analog input value | Parameter 182 |

| 25 | 618 | 1581 mV | 1962 |

| 100 | 1000 | 1185 mV | 1470 |