meta data for this page

Elmo Servo Drive

Installation with Elmo Gold DC Bell

Feedback

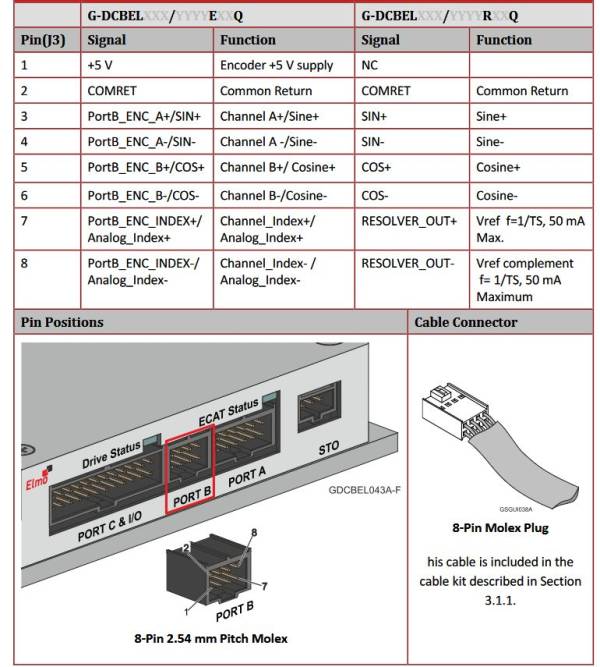

The motor feedback must be connecte to the feedback port (DC Bell in port B) with the adapter cable with code DA002030-1M.

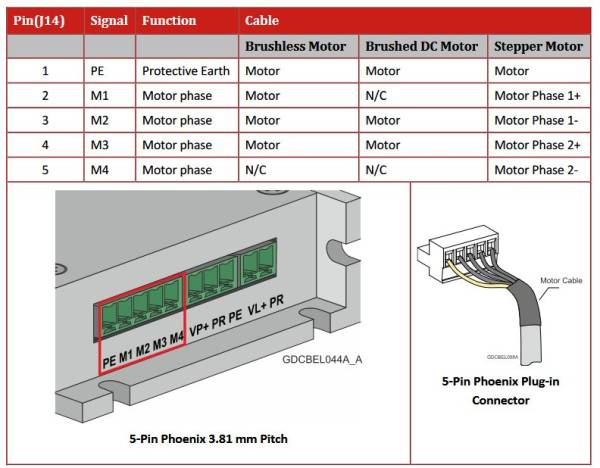

Motor phases

M1,M2 and M3 must be connected respectively to U, V and W phases of the linear motor.

Considering the adapter cable DA002030-1M the phases color are M1 ⇒ blue, M2 ⇒ violet and M3 ⇒ brown.

Configuration

In order to configure ELMO servo drive for NL miniature linear motor following these steps using ELMO Application Studio II from ELMO: https://www.elmomc.com/products/application-studio/download-resource-center/

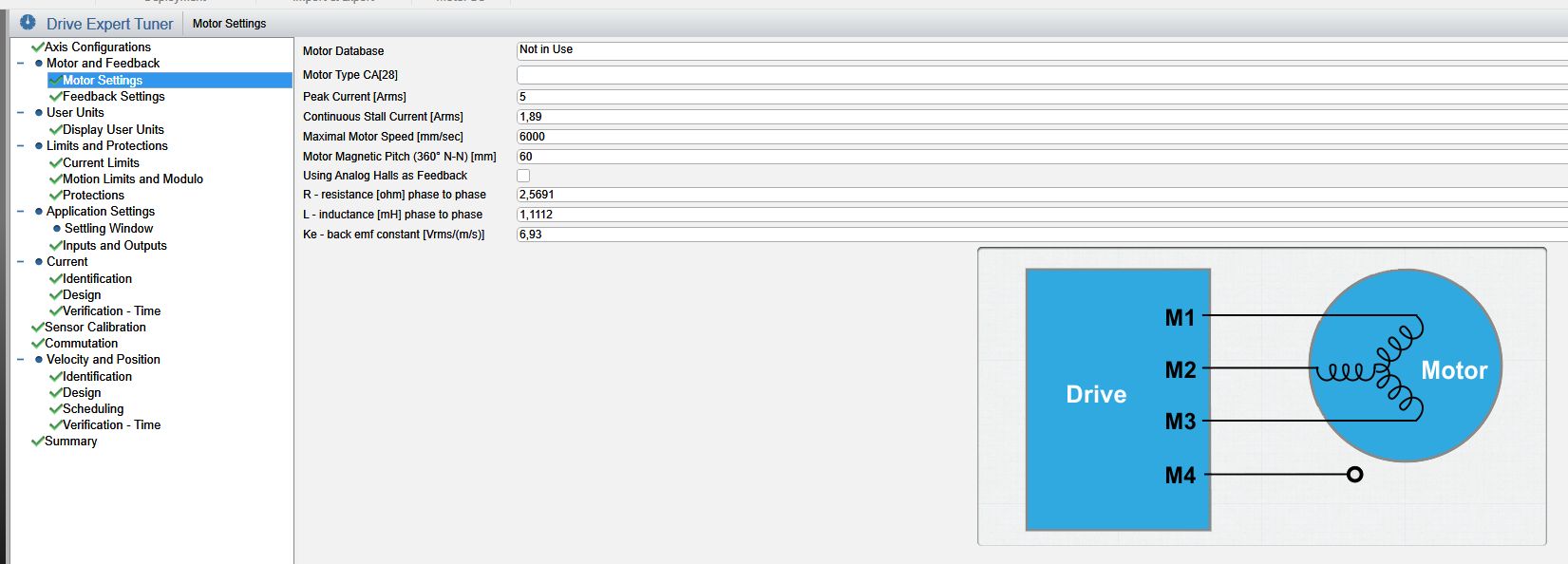

Motor Settings

Using the data from NL datasheet please insert the right values on the page. For example considering NL120Q we have these values.

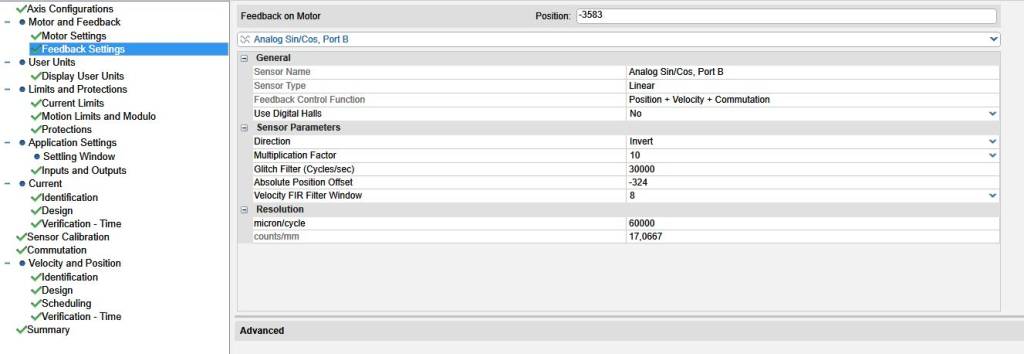

Feedback settings

Integrated encoder is SIN/COS 1Vpp connected to the Port B of the drive (here the drive is Gold DC Bell) with a sine period that correspond to 60 mm of pole pitch (NL120Q)

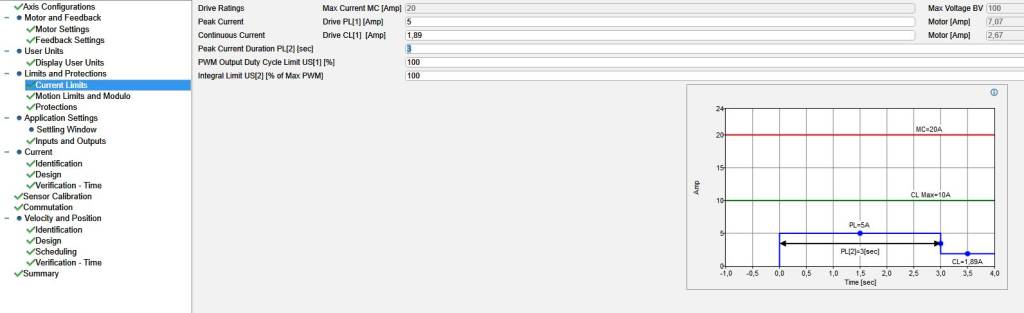

Current LImits

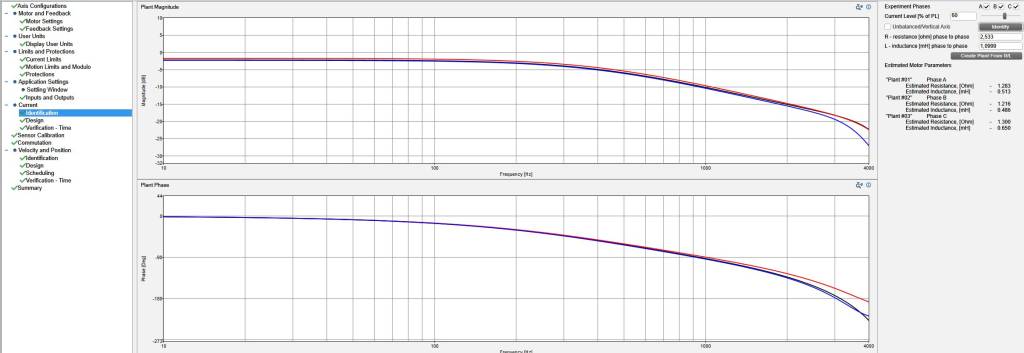

Current Indentification

Please perform current identification pushing Indentify button on the right up of the window. The drive calculates the phase resistance and induction of the single phase.

The resulted values are the original Phase to Phase resistance and inductance divided by a factor of 2.

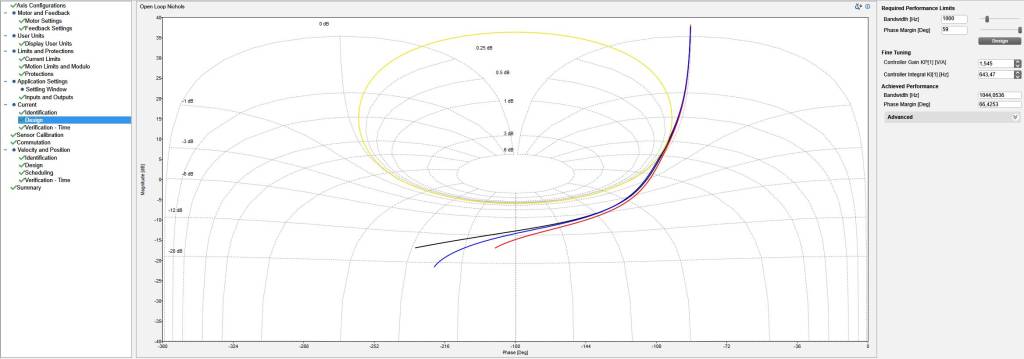

Current Design

Please push the button Design on the right up of the window to perform a calculation of current loop parameters.

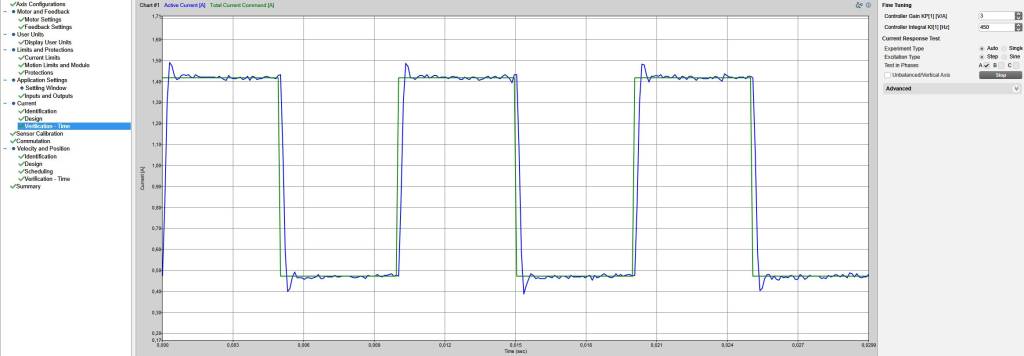

Current Verification - Time

Click on start button on right up of the window to start the verification. The drive is injecting a square wave in a current loop. Please change the values controller gain and controlled integral to be close to the injected square wave profile (green)

The target is to have minimum overshot and maximum slope on the current feedback signal (blue)

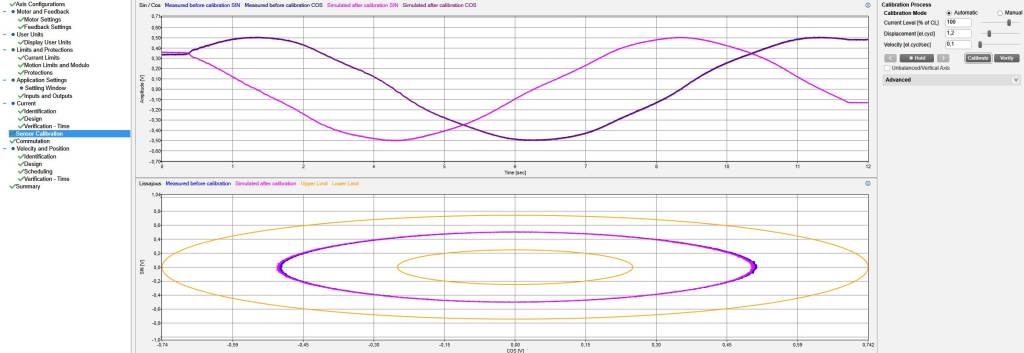

Sensor Calibration

Please specify the right displacement for this calibration, typically at least one sine period ⇒ Displacement [el.cycl] = 1,2.

Then move the slider of the motor in a position to avoid the mechanical stop interaction. With 1,2 on the displacement the motor will be move forward and backward for motor pole pitch x 1,2 = 60 x 1,2 = 72mm.

When the motor is in the right position please press the button calibrate.

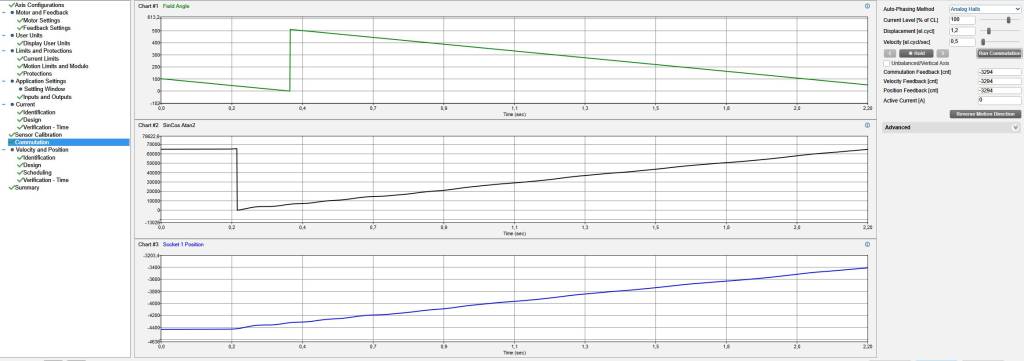

Motor commutation

In order to calculate a store the commutation offset move the slider in a position to avoid the mechanical stop interaction and press the button Run commutation on the right up of the window.

The slider will move for a corresponding span of 1,2 x pole pitch = 1,2 x 60 = 72mm. (the span can be reduces using the parameter Displacement [el.cycl].

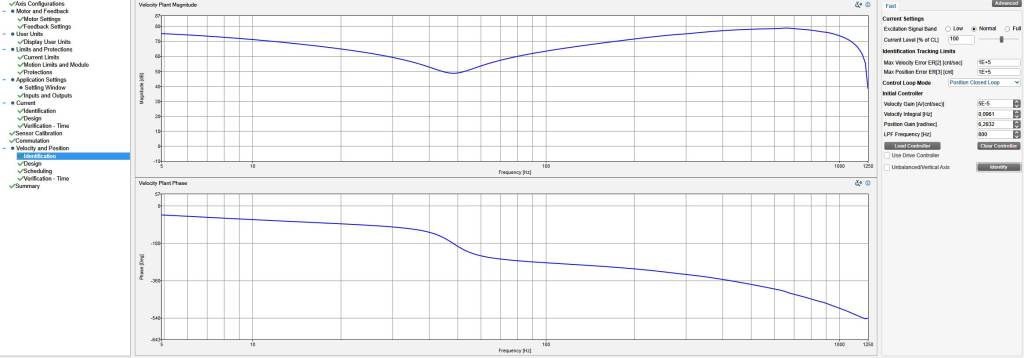

Velocity and position identification

Perform a verification setting control loop mode to Position Closed Loop with a low pass filter value of 800 Hz (typical value for NL120).

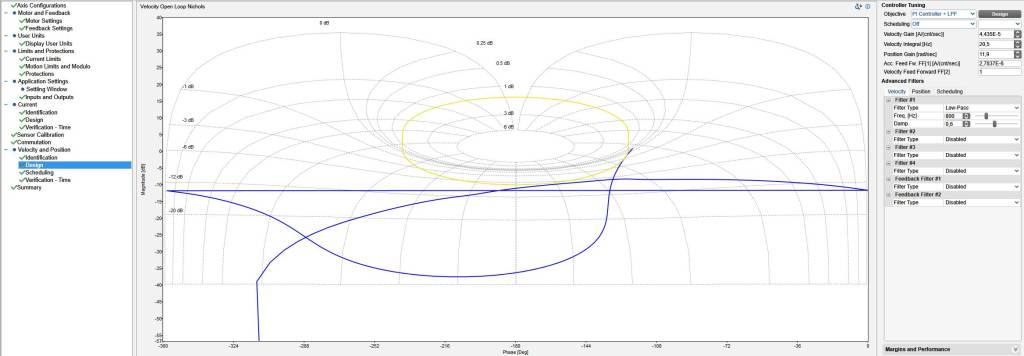

Velocity and position design

Please press the button design to calculate the position and velocity values.

Normally, the velocity integral must be increase to increase the stiffness of the slide. Please, enable the motor and increase the value to have slider rigidity.

Typicall 500 Hz of velocity integral are needed.

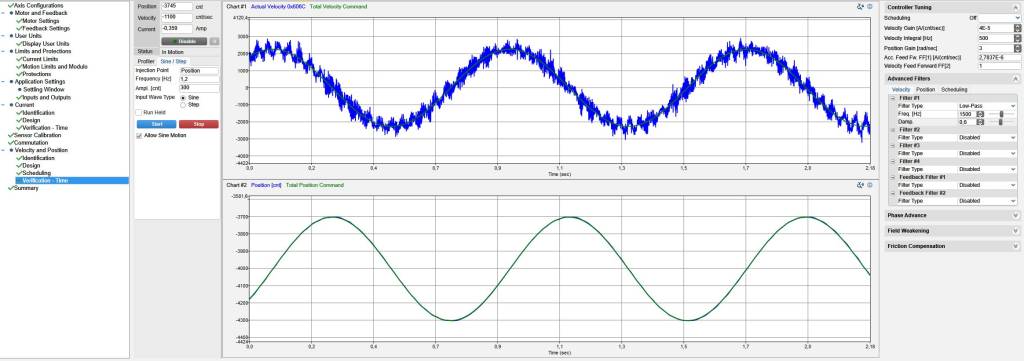

Velocity and position verification - Time

In order to fine tune the motor, please use Verification time window injecting a sine wave on the position loop correspoding to at least 300 counts with a frequency of 1,2 Hz (for example).

See the result on the signal position command and position feedback, speed command and speed feedback. Oscilloscope setting are resolution of 800 microseconds with a record time of 2,183sec.

The typical value for NL120Q are: :miniature_motors:nl120q_elmo_dcbell.zip

Velocity gain [A/count/sec] = 4E-5

Velocity integral [Hz] = 500

Position gain [rad/sec] = 3

Acceleration feed FW [A/count/sec] = 2,78E-6

Velocity Feedfoward FF[2] = 1

Low pass filter Freq. [Hz] = 1500

Damping factor = 0,6